Rockwell Automation (Allen Bradely) Hardware /Software :-

Software

The foundation for your industrial digital transformation

FactoryTalk Metrics

Help Improve Plant OEE with Self-Service and Customizable Reports FactoryTalk® Metrics is a system for efficiency monitoring, data collection and analysis for manufacturing plant equipment. It gives you the critical equipment data that can reveal new ways to increase production, reduce costs, and increase quality. By generating accurate reporting of real plant floor activity, this software gives you important insights into using existing equipment and labor more effectively. FactoryTalk Metrics reports on OEE, but it is more than just an OEE reporting tool. Beyond high-level KPIs, FactoryTalk Metrics supports answering the "why" questions, to uncovering and quantifying the actual causes of downtime and loss to help you make real improvements to performance.

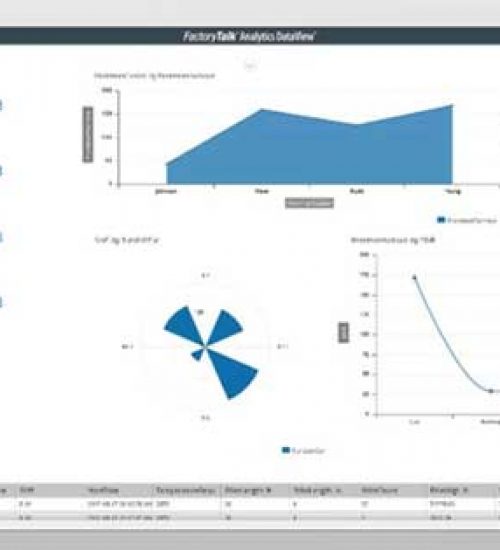

FactoryTalk Analytics

A Full-stack Analytics Platform for Achieving Your Industrial Outcomes FactoryTalk® Analytics™ provides industrial manufacturing practitioners with a complete spectrum of descriptive to prescriptive analytics solutions for achieving business outcomes such as overall equipment effectiveness (OEE) improvement, downtime reduction, and quality or process improvement. FactoryTalk Analytics also integrates seamlessly with the InnovationSuite Augmented Reality and MES solutions to bring actionable insights to the shop floor and optimize the supply chain operations at the enterprise level.

FactoryTalk Historian

Operational Historian Software FactoryTalk Historian Gives You a Powerful Plant Floor Reporting Tool It is time to retire the warn-out clip boards and tedious transcription of critical plant performance data. FactoryTalk® Historian software captures operational process data from multiple sources at lightning speed. You gain a supreme level of supervisory control, performance monitoring and quality assurance with robust FactoryTalk Historian software that can scale from machine to enterprise. Reliably recording time-series records at this pace would be impossible, even for your most caffeinated plant-floor record keeper. FactoryTalk Historian dashboards take that work off your hands. Plus, the added confidence in forecasting trends with reliable data will generate new level of productivity. So long, clip boards. You won’t be missed.

FactoryTalk Design Tools

Our Next, Fueling Your Next Simplify your workflows with our next innovations Get ready to reclaim your time and simplify your workflows with OUR NEXT innovations. Think design software, emulation, and cloud services! Be sure to sign up below to get on the inside track to hear about major milestones, be invited to private previews, and take a sneak peek behind the curtain along the pathway to YOUR NEXT. The arrival of FactoryTalk Design Tools and FactoryTalk Vault Streamlined workflows. New ways to inspect and analyze project files. Secure industrial file storage. We're combining our imagination and the needs of our customers with the potential of technology. FactoryTalk® Design Tools™, part of FactoryTalk® Design Hub™, and FactoryTalk® Vault™ are available at no extra cost to Studio 5000® design environment customers with a maintenance or support agreement. These product introductions mark our first step in delivering next-generation cloud technology. Studio 5000 Logix Designer® is an intuitive programming environment that allows users to work collaboratively to design and maintain their systems. Studio 5000 View Designer® is the design environment for the PanelView™ 5000 family of operator terminals. With Studio 5000 Architect®, you can jump-start your initial system creation for your control and visualization applications. Studio 5000® Application Code Manager is a tool that enables more efficient project development with libraries of reusable code.

Studio 5000®

Automation System Design Software Enhance Productivity and Reduce Commissioning Time with Studio 5000 The Studio 5000® environment combines elements of design into one standard framework that optimizes productivity and reduces time to commission. This intuitive integrated design environment focuses on rapid design, re-use, collaboration and virtual design. The updated user interface provides a common, modern user experience across all Studio 5000 applications. Studio 5000 Logix Designer® is an intuitive programming environment that allows users to work collaboratively to design and maintain their systems. Studio 5000 View Designer® is the design environment for the PanelView™ 5000 family of operator terminals. With Studio 5000 Architect®, you can jump-start your initial system creation for your control and visualization applications. Studio 5000® Application Code Manager is a tool that enables more efficient project development with libraries of reusable code. With Studio 5000® Logix Emulate™ you can validate, test and optimize application code independent of hardware. Studio 5000 Simulation Interface connects controllers – physical or emulated – to simulation and modeling tools to enable virtual commissioning and model-based design.

FactoryTalk View - HMI Software

Serve Up Real-time Performance Information Those machines that spread all across our plant floor and enterprise are telling you something. With FactoryTalk® View software, you can get a clear consistent story from the standalone machine level HMI to distributed visualization solutions covering your entire enterprise. A single software package covers HMI challenges in process, batch and discrete application. Clear displays and a common programming language, including a huge library of faceplates, help confirm that you get the best possible perspectives of your machine performance. With users at multiple levels in your organization all seeing the same views of the machines, you speed up the ability to manage production…which is a story you can all get behind. HMI Solutions Designed with Your Success in Mind It All Starts with a Human With an evolving industry, changes in processes, operation expansion and more, determining how to grow in this era can be challenging. Built for today’s challenges and tomorrow’s opportunities, our HMI solutions are designed with you and your success in mind. The first word in HMI is human, and at Rockwell Automation that’s where it all begins. Driving Better Decision Making Modern HMI Software: Connecting People to Information Good things happen when operators, technicians and engineers have relevant production information at their fingertips. They can meet production targets, reduce waste and energy usage, improve processes, quickly resolve problems, and more. This eBook explores how Modern HMI Software makes this possible.

FactoryTalk Linx

FactoryTalk Linx Delivering data from the control products to the control system All those ones and zeros traveling through industrial networks from one automation asset to another is what brings your industrial operations to life. Securely transporting that data and successfully reconstructing it at it’s intended destination is what keeps your operations humming. And industrial communication is at the heart of it all. Without it, monitoring, managing, controlling, and securing your operations would be an impossibility. FactoryTalk® Linx provides an indispensable foundation for all things that speak FactoryTalk (and even those third-party devices that are integral partners in your industrial ecosystem). Industrial Comms that Deliver the Goods FactoryTalk Linx delivers a solution from small applications running on a single computer with a single controller, to large distributed and even redundant data server configurations communicating with large automation systems.

FactoryTalk Network Manager

Providing Visibility to Your Network Are you looking for a software solution that provides the ability to support the operation and maintenance of your network-based assets? FactoryTalk® Network Manager™ software helps you get a better look into your network, so you can efficiently manage and make more informed decisions regarding your plant floor. Get a Better View of What is Happening in Your Facility FactoryTalk Network Manager software helps to achieve increased network visibility, easier troubleshooting, and simplified configuration and maintenance. Get insight into your network operations by getting a closer look at your devices connected in your manufacturing environment. Increased Network Visibility Ethernet networks have become a critical part in automation control systems where plant floor staff is often tasked with the network operations and maintenance. FactoryTalk Network Manager provides the information these control engineers need to achieve increased reliability and high performance of the network.

FactoryTalk Analytics for Devices

Monitor Device Health for Proactive Asset Maintenance FactoryTalk® Analytics™ for Devices gives you a quick look into the health of your control system devices, enabling you to improve downtime planning and asset availability. Simply put, data isn’t useful unless it’s helping you take your decision-making at the right time and take operational performance to the next level. That’s what analytics can do for you – and FactoryTalk Analytics for Devices is a great place to start because it will provide insightful diagnostics immediately upon connecting to your plant assets. FactoryTalk Analytics for Devices is an industrial information appliance with automated diagnostics, built-in dashboards and a chatbot that helps you get value from your asset data. The appliance also supports data egress through a REST-based API, so it can be leveraged as a critical data source for improving enterprise level planning and supporting active notifications.

Hardware

Distributed Control System

PlantPAx

The PlantPAx® system helps producers make better, faster process control decisions. This system enables you to respond more quickly to the demands of your customers and fast-changing specifications. The latest system release has been designed to be an integral part of your digital transformation strategy that helps you be more productive and profitable while reducing operational risk. Rethink what a modern distributed control system (DCS) can do for you. PlantPAx 5.0 Accelerate Your Digital Transformation with Our Latest DCS Version Producers like you are adept at navigating the complexities and challenges of staying competitive. This is true in a variety of industries ranging from pharmaceuticals, consumer packaged goods, and food and beverage to mining and chemical. That’s why it’s so important to implement the latest technological advancements to continue your ever-evolving digital transformation journey. From the control room to the board room, process system users face the persistent challenges of balancing productivity against budget and resource constraints as well as proactively addressing evolving operational risks. Meet these challenges and experience real productivity gains in all areas of your plant with the PlantPAx distributed control system (DCS).

Input/Output (I/O) Modules

Chassis-Based I/O

SLC I/O Modules

Our Bulletin 1746 SLC™ I/O Modules are part of our SLC 500 control platform. Rockwell Automation announces that as of August 31, 2018, additional Bulletin 1746 I/O modules will be discontinued and no longer available for sale. Customers are encouraged to migrate to our Compact 5000™ I/O modules used with the Logix control platform.

ControlLogix Modules

Our Bulletin 1756 ControlLogix® chassis-based modules provide a full range of digital, diagnostic digital, analog, motion control, specialty I/O, and compute modules to meet your application needs. You can use any of the chassis-based modules in the local chassis of a ControlLogix controller or in a chassis linked to a ControlLogix controller across ControlNet™ or EtherNet/IP™ networks.

MicroLogix Expansion I/O Modules

Our Bulletin 1762 MicroLogix™ Expansion I/O Modules extend the capabilities of the MicroLogix 1100, 1200, and 1400 controllers by maximizing flexibility of the I/O count and type. The modular, rackless design enhances cost savings and reduces replacement parts inventory. Modules can be either DIN rail or panel mounted.

Compact I/O Modules

Our Bulletin 1769 Compact I/O™ chassis-based modules can be used as local and distributed I/O for a 1769 CompactLogix™ L3x, CompactLogix 5370 or Compact GuardLogix® 5370 controller. Rack-type features in a rackless design lower costs and reduce replacement parts inventory. A built-in removable terminal block provides connections to I/O sensors and actuators.

Compact 5000 I/O Modules

Our Bulletin 5069 Compact 5000™ I/O modules provide high-performance control in a compact design, and expand the performance capabilities of the Logix platform. They are the local I/O modules in a CompactLogix™ 5380, Compact GuardLogix® 5380, or CompactLogix 5480 system and safety options are available. These modules are the ideal distributed I/O solution on an EtherNet/IP network for CompactLogix 5380, Compact GuardLogix® 5380, CompactLogix 5480, ControlLogix® 5580, and GuardLogix 5580 controllers with safety module restrictions. They are great for applications with high-processing requirements.

Micro800 Expansion I/O Modules

Our Bulletin 2085 Micro800™ Expansion I/O modules extend the capabilities of the Micro850® and Micro870® controllers by maximizing flexibility of the I/O count and type. The I/O module snaps firmly to the right side of Micro850 and Micro870 controllers, supporting both DIN rail and panel mount.

PLC Programmable Controllers

Allen‑Bradley® programmable logic controller (PLC) and programmable automation controller (PAC) range from large to small and even micro applications. We offer different controller types and sizes to fit your specific needs.

Large Control Systems

ControlLogix 5580 Controllers

A modern control system is more than its name implies. It delivers the fast system performance, high capacity and optimized productivity that you need from a control system today. Our ControlLogix® and GuardLogix® 5580 family of controllers use the Studio 5000® design environment as the standard framework that optimizes productivity, reducing time to commission. This framework manages Integrated Motion over EtherNet/IP for high-speed motion applications and SIL2/PLd and SIL3/PLe safety solutions.

Process Controllers

The PlantPAx® 5.0 distributed control system (DCS) introduces new process functionality native to controllers, cyber-secured architectures, and improved system availability and workflows. These benefits help reduce the complexity of traditional DCS and overall costs at all phases of the plant lifecycle for hybrid and Process industries. Accelerate your digital transformation with our latest PlantPAx® 5.0 DCS version and unlock more opportunities with our ControlLogix® 5580 and CompactLogix™ 5380 Process controllers.

ControlLogix 5570 Controllers

A modern control system is more than its name implies. It delivers the fast system performance, high capacity and optimized productivity that you need from a control system today. Our ControlLogix® and GuardLogix® 5580 family of controllers use the Studio 5000® design environment as the standard framework that optimizes productivity, reducing time to commission. This framework manages Integrated Motion over EtherNet/IP for high-speed motion applications and SIL2/PLd and SIL3/PLe safety solutions.

Small Control Systems

CompactLogix 5480 Controllers

Our Bulletin 5069 CompactLogix™ 5480 controllers are real-time controllers with Windows 10 IoT Enterprise running in parallel to the Logix control engine. Our CompactLogix 5480 uses the same re-architected control engine deployed in the ControlLogix® 5580 and CompactLogix 5380 controllers. This line of Logix controllers supports embedded Windows applications, such as analytics, data gathering, and predictive computations. The ability to collect data and make decisions at the machine level helps to support the Connected Enterprise and benefits both end users and OEMs.

CompactLogix 5380 Controllers

Our CompactLogix™ and Compact GuardLogix® 5380 controllers provide higher performance, increased capacity, improved productivity and enhanced security to help meet the growing demands of smart machines and equipment for manufacturing. All standard and safety controllers use a modern programming environment, Studio 5000 Logix Designer® application, to allow users to work collaboratively to design and maintain their systems. This common environment optimizes efficiency, reduces time to commission and manages integrated motion over EtherNet/IP™ for high-speed motion applications and up to SIL 3/PLe safety solutions. These controllers are ideal for applications requiring high-performance communications, I/O and motion control for up to 32 axes.

Process Controllers

The PlantPAx® 5.0 distributed control system (DCS) introduces new process functionality native to controllers, cyber-secured architectures, and improved system availability and workflows. These benefits help reduce the complexity of traditional DCS and overall costs at all phases of the plant lifecycle for hybrid and Process industries. Accelerate your digital transformation with our latest PlantPAx® 5.0 DCS version and unlock more opportunities with our ControlLogix® 5580 and CompactLogix™ 5380 Process controllers.

CompactLogix 5370 Controllers

Our Bulletin 1769 CompactLogix™ 5370 Controllers are part of the Integrated Architecture® system. These controllers include integrated safety, and use the same programming software, network protocol, and information capabilities as all Logix controllers. This provides a common development environment for all control disciplines. Consistent tools and features help users to lower engineering investment costs, ease diagnostics and troubleshooting, and speed up time to market for small to mid-size applications.

SmartGuard 600 Safety Controllers with Safety

Our Bulletin 1752 SmartGuard™ 600 Controllers with Safety feature 16 safety-rated inputs, 8 safety-rated outputs, 4 pulse test sources and an optional EtherNet/IP™ port. Each controller also includes a DeviceNet™ connection to support both standard CIP and CIP safety. You can configure and program on EtherNet/IP, on DeviceNet or through the built-in USB port. These small, cost-effective intelligent controllers can perform safety interlocking between GuardLogix® or other SmartGuard safety controllers.

SLC 500 Controllers

Our Bulletin 1747 SLC™ 500 control platform is used for a wide variety of applications. Rockwell Automation has announced that some SLC 500 Bulletin numbers are discontinued and no longer available for sale. Customers are encouraged to migrate to our newer CompactLogix™ 5370 or 5380 control platforms.

Micro Control Systems

Micro870 Programmable Logic Controller Systems

Our Bulletin 2080 Micro870® Programmable Logic Controllers are designed for large standalone machine control applications that require flexible communications and greater I/O capabilities. These controllers support up to 304 I/O points with high performance I/O, interrupts, and Pulse Train Output (PTO) motion plus embedded Ethernet port and Bulletin 2085 expansion I/O modules.

Micro850 Programmable Logic Controller Systems

Our Bulletin 1752 SmartGuard™ 600 Controllers with Safety feature 16 safety-rated inputs, 8 safety-rated outputs, 4 pulse test sources and an optional EtherNet/IP™ port. Each controller also includes a DeviceNet™ connection to support both standard CIP and CIP safety. You can configure and program on EtherNet/IP, on DeviceNet or through the built-in USB port. These small, cost-effective intelligent controllers can perform safety interlocking between GuardLogix® or other SmartGuard safety controllers.

Micro830 Programmable Logic Controller Systems

Our Micro830® Programmable Logic Controller Systems are designed for stand-alone machine control applications that require flexible communications and I/O capabilities. These controllers support up to 88 I/O points with high performance I/O, interrupts, and PTO motion.

Micro820 Programmable Logic Controller Systems

Our Micro820® Programmable Logic Controller Systems include a nano-sized footprint and are designed for small standalone machine control and remote automation applications that require flexible communications and I/O capabilities. These controllers support up to 36 I/O points with many embedded features such as Ethernet, microSD slot for recipe and data log, and analog I/O.

Micro810 Programmable Logic Controller Systems

With a nano-sized footprint, our Bulletin 2080 Micro810® Programmable Logic Controller Systems function as smart relays with high-current relay outputs, but with the programming capabilities of micro-PLCs. These controllers support 12 I/O points with 4 high current relay outputs (8A) for smart relay applications.

Micro800 PLC Plug-in Modules and Accessories

With our Bulletin 2080 Micro800™ Programmable Logic Controllers Plug-in Modules and Accessories, you can adapt your base unit controller to fit your application needs. Extend the functionality of embedded I/O without increasing the footprint of your controller. Increase the system capabilities through memory and clock modules.

MicroLogix 1400 Programmable Logic Controller Systems

Our Bulletin 1766 MicroLogix™ 1400 Programmable Logic Controller Systems build upon critical MicroLogix 1100 features: EtherNet/IP™, on-line editing and a built-in LCD panel. These controllers feature a higher I/O count, faster high-speed counter, pulse train output, enhanced network capabilities and backlight on the LCD panel. Controllers without embedded analog I/O points provide 32 digital I/O points, while analog versions offer 32 digital I/O points and 6 analog I/O points. You can expand all versions with up to seven 1762 expansion I/O modules.

MicroLogix 1100 Programmable Logic Controller Systems

Rockwell Automation announces that as of April 2022, our Bulletin 1763 MicroLogix™ 1100 controllers will be discontinued and no longer available for sale. Customers are encouraged to migrate to our Micro800™ control platform. Product Compatibility and Migration Solutions Demanding market conditions pose significant challenges. Across the enterprise and throughout the lifecycle, you must continuously strive for ways to leverage your existing automation investment.

Safety Products

Rockwell's innovative safety products and solutions improve the functional operation of your machinery while helping to increase personnel safety, efficiency and productivity. We offer one the broadest safety portfolios in the industry to help you achieve both safety and productivity goals in process and discrete manufacturing applications.

Safety Programmable Controllers

Our safety control systems bring the benefits of traditional programmable control to complex safety applications, replacing the hard-wired relay systems normally required to bring automated processes to a safe state.

Safety Input/Output (I/O) Modules

Our safety I/O portfolio offers local, distributed and On-Machine™ options with a wide range of performance and connectivity attributes to help improve compliance and machine performance.

GuardLink Technology

GuardLink™ technology is a safety-based communications protocol that helps enhance safety and increase machine- and plant-wide efficiency.

Safety Connection Systems

Our Guardmaster® Safety t-ports/splitters, distribution boxes, shorting plugs, and taps are parts of a quick-disconnect system dedicated to machine safety.

Safety Drives

To help you protect both your personnel and equipment, a variety of PowerFlex® drives are available with safety features. Additionally, you can configure drives without a safety option using the MSR57P Safety Relay.

Safety Motion Control

Our Safety Servo Drive products are designed to help minimize downtime and reduce energy and production waste while helping improve machine operating efficiencies.

Safety Motor Control

Our Safety Motor Control products help reduce the risks associated with the operation and maintenance of electrical equipment.

Presence Sensing Safety Devices

Our Presence Sensing Safety Devices detect the location of objects or personnel near hazardous areas.

Safety Relays

Safety Relays check and monitor a safety system and either allow the machine to start or execute commands to stop the machine.

Human Machine Interface

Visualization for Smart Manufacturing

Graphic Terminals

Our Graphic Terminals offer rugged electronic interface solutions in a variety of sizes, operator input methods and configurations. These robust devices are fully packaged (hardware, software and communications) and tested for human-machine interface operation. They have earned ratings for high shock, vibration, and temperature.

Tethered Operator Terminals

Our MobileView™ Tethered Operator Terminals are mobile devices that help increase operator productivity and provide a safe production environment. The mobile operator interface runs the Windows Embedded Standard 7 operating system, but allows reuse of FactoryTalk® View ME and FactoryTalk View Studio applications to help reduce development costs.

Industrial Computers and Monitors

Visualization and computing products provide windows into critical production and process information and enterprise data. Across every type of industry, application and manufacturing environment, these products accelerate development and enhance operation.

Network Security & Infrastructure

Rockwell Automation offer network and security solutions to connect your automation products to each other and to the rest of your enterprise. We can help you select the best network architecture and provide you with design and implementation guidance. We offer a wide variety of devices, communication interfaces, physical media and connecting products to help you get the most out of your control system.

Chassis-based Communication Modules

Our ControlLogix® system uses connections to establish communication links between devices. Our Bulletin 1756 Chassis-based communication modules help make those connections and implement network-based access control for users, devices, and networks in the 1756 chassis. We offer a variety of modules that support EtherNet/IP, DeviceNet, ControlNet, and other network protocols.